Stripping Some Bigger Parts

Depending on the size and material the part is made of I use different processes to remove the original paint and corrosion etc.

Most of the sheet aluminum parts will be stripped using paint stripper or soda blasted.

I use the soda sparingly on hard to reach places after stripping or sanding. It does a great job but it uses a lot of soda and in Canada the soda is expensive and with the border to the USA closed to entry for Canadians I can't get to my regular source.

I used a paint stripper I bought at AirVenture a number of years ago named Ez Way paint remover and it really worked well on the original dope finish. It does not seem as harsh as other systems I have used and it does not have to be neutralized by water.

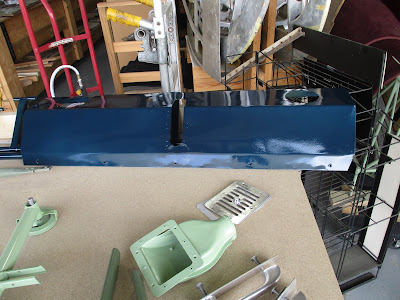

Ready for a coat of blue the way it was finished at the factory

I thought I would strip the panel layover. This is one I picked up on E Bay a few years ago. It is stock with no extra holes or modifications. I stripped it with the EZ Way product It cleaned up nice.